Overview

This project explores and extends Canon’s internal camera control architecture by building a custom Camera Control Unit (CCU) that interfaces with the Canon Extension System Terminal. The CCU exposes deterministic, tactile control over modern network links, enabling reliable multicamera operation on bodies that predate Canon’s built‑in browser control.

The project matters because Canon’s transition to network‑native control leaves a gap for legacy and transitional cameras (notably the R5C) and for workflows that require physical controls, predictable latency, and mixed camera generations.

Personally, I have multiple Canon camera bodies that I would like to remotely control alongside my DJI PTZ rigs (see the DJI Ronin Gimbal Control Surface project). By using this port to access camera data, I can wirelessly control those cameras from a central hub.

Many Canon bodies deliver strong video performance that rivals or exceeds older broadcast systems (for example 3‑chip or 2/3‑inch sensor cameras), but the missing piece compared to true broadcast rigs is CCU‑style remote drive and control.

Problem

Canon’s control ecosystem is fragmented across generations:

- Older professional bodies relied on an undocumented Extension System Terminal for grips and wireless file transmitters.

- Newer cameras introduce browser‑based network control, optimized for tablets and phones rather than physical CCUs.

In multicamera workflows—classical music, live performance, houses of worship, education, and experimental rigs—this creates problems:

- Inconsistent control methods across cameras

- Non‑deterministic latency from browser UIs

- Poor support for tactile, eyes‑off operation

- No unified control plane for mixed camera generations

Hardware

CCU Controller

- ESP32 LoRa development boards with integrated Wi‑Fi and Ethernet capability

- Long‑range sub‑GHz LoRa radios for control

- Adequate GPIO and peripheral bandwidth

- Mature firmware and tooling ecosystem

The ESP32 acts as the control brain, normalizing camera state and translating physical inputs into camera commands.

Wireless Control

- Wi‑Fi / Ethernet: High‑bandwidth local control and integration with modern IP workflows

- LoRa: Long‑range, low‑bandwidth, highly reliable CCU command channel (record, tally, presets, camera selection)

Control latency is intentionally decoupled from video transport.

Camera Interface

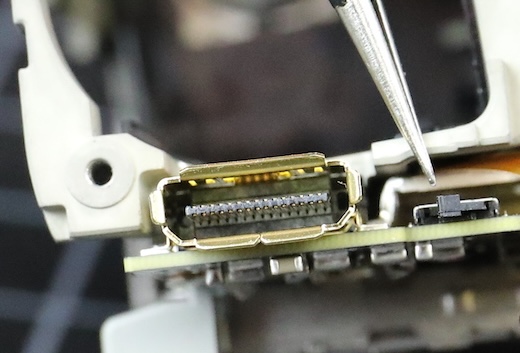

The CCU interfaces with Canon cameras via the Extension System Terminal, a custom, fine‑pitch 30‑pin board‑to‑board mezzanine connector historically used by Canon Wireless File Transmitters (WFT) and later by advanced battery grips.

- Custom, Hirose‑class connector (OEM‑only)

- 30‑pin port

- Multiple grounds and logic power rails

- Grouped low‑speed digital signaling lines

- Tight mechanical tolerances (not probe‑friendly)

Power System

Development hardware is powered using:

- Li‑ion cells (18650 or pouch)

- TP4056 charging and protection modules

- Regulated 5 V rails feeding ESP32 boards

This ensures stable operation during RF bursts and long capture sessions.

Physical Controls

- Buttons, encoders, and joystick inputs

- Planned integration with a dedicated CCU panel and ATEM‑based control case

Protocol / Reverse Engineering

Discovery

The Extension System Terminal was identified across multiple Canon generations, including DSLR bodies (5D Mark II, 7D) and modern hybrids (R5C). Official Canon WFT units provided a known‑good reference implementation.

Methodology

- Disassembled official (WFT‑E4 II) and third‑party grip accessories

- Traced 30‑pin connector lines to downstream components (MCUs, PHYs, regulators)

- Identified ground, logic power, and grouped signal lines

- Avoided direct probing of camera‑side connectors

- Used logic analysis at safe downstream test points

Key Findings

- The protocol is low‑speed, deterministic, and structured

- Designed for reliability over bandwidth

- Consistent signaling behavior across generations

- Capable of both simple control (buttons/dials) and sustained data transfer (Ethernet on WFT)

Control Bridge Design

The CCU implements a control‑only bridge rather than a full wireless file transmitter:

- Speaks the same legacy control protocol on the Extension System Terminal

- Normalizes camera state into an internal model

Exposes control via:

- Wi‑Fi / Ethernet

- Long‑range LoRa

- Physical control surfaces

This creates a parallel control plane optimized for latency, reliability, and tactile operation.

The CCU also enables multi‑camera control through a web app server. As additional camera protocols are decoded, the system can expand to multiple brands with a unified, web‑based CCU that manages diverse camera fleets.

Diagram (Conceptual)

Key Features

- Tactile control: Buttons, encoders, and joystick for eyes‑off operation

- Deterministic latency: No browser, no event‑loop jitter

- Multicamera scaling: One CCU controlling many cameras

- Mixed generations: Legacy and modern Canon bodies in one system

- Long‑range operation: Reliable CCU control over LoRa

Challenges

- Proprietary, OEM‑only connector with no public part number

- Undocumented signaling and pin assignments

- Safe probing of fine‑pitch interfaces

- Maintaining electrical and mechanical safety for camera bodies

- Avoiding scope creep into wireless video transport

Stack

- Microcontroller: ESP32

- Wireless: Wi‑Fi, LoRa

- Power: Li‑ion, TP4056, regulated 5 V rails

- Tools: Logic analyzer, multimeter, teardown analysis

- Control: Custom firmware, physical CCU surfaces

Outcome

Today, the CCU:

- Successfully interfaces with Canon’s Extension System Terminal

- Demonstrates deterministic, networked control of legacy cameras

- Bridges pre‑network Canon control into modern IP workflows

- Provides a foundation for unified, hardware‑first camera control

Next Steps

- Expand support to additional camera bodies from various brands

- Complete a dedicated physical CCU panel

- Firmware refinement and documentation

- Explore USB‑C and API‑based control on newer cameras

- Hybrid control layer spanning legacy ports and modern network APIs